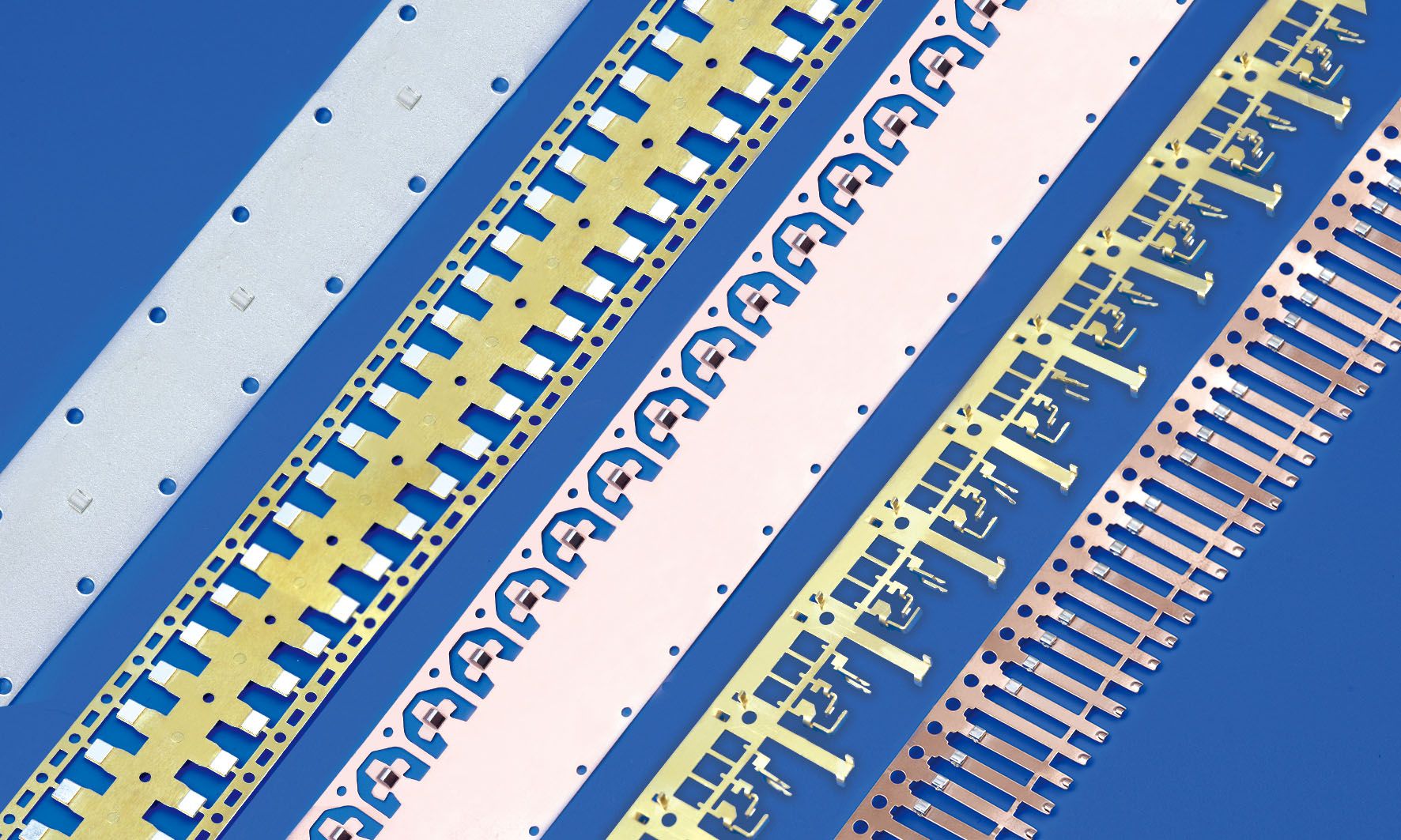

PRODUCT

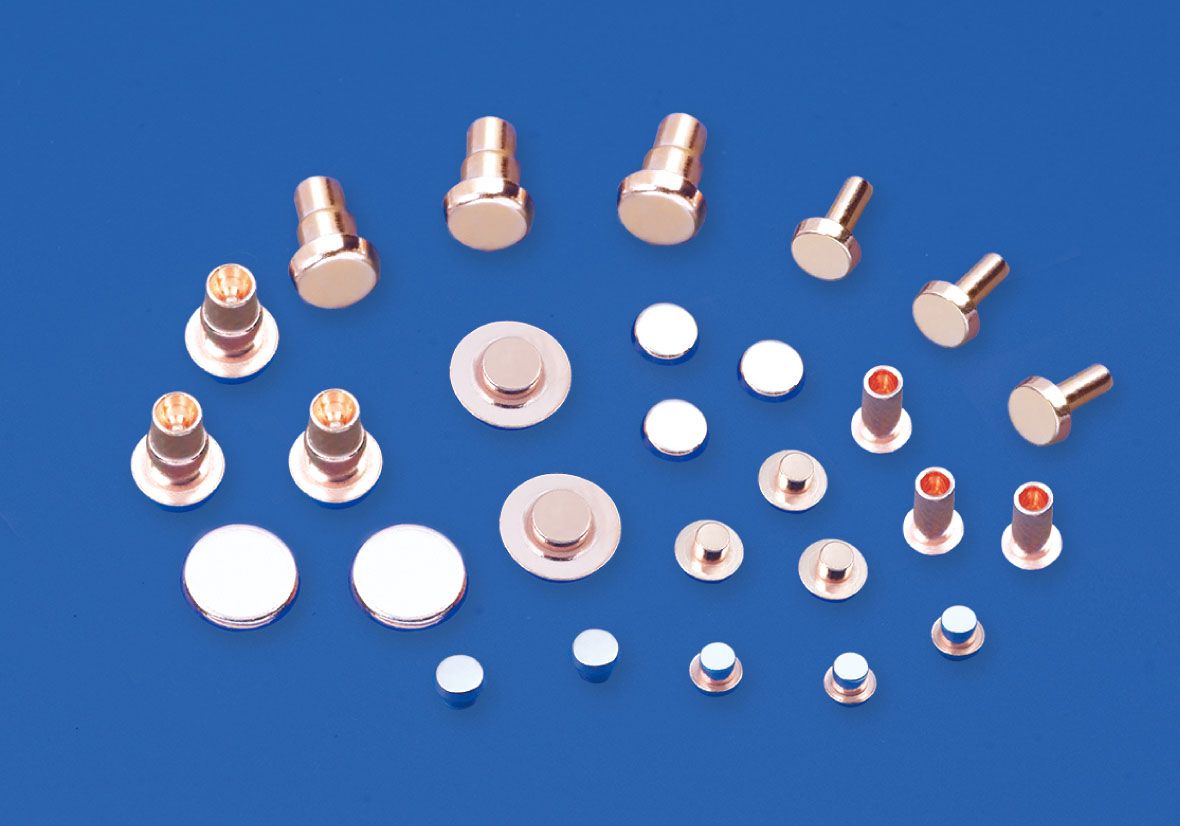

Silver contact

Silver contact

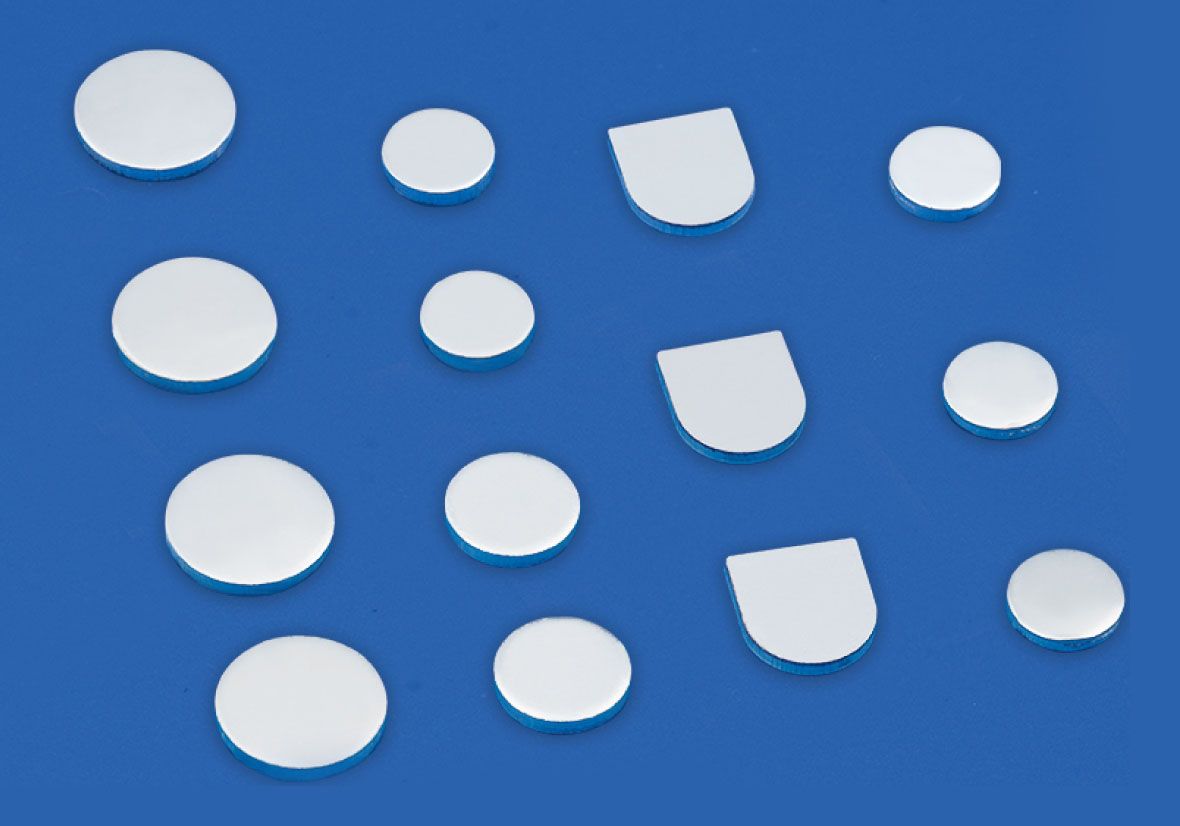

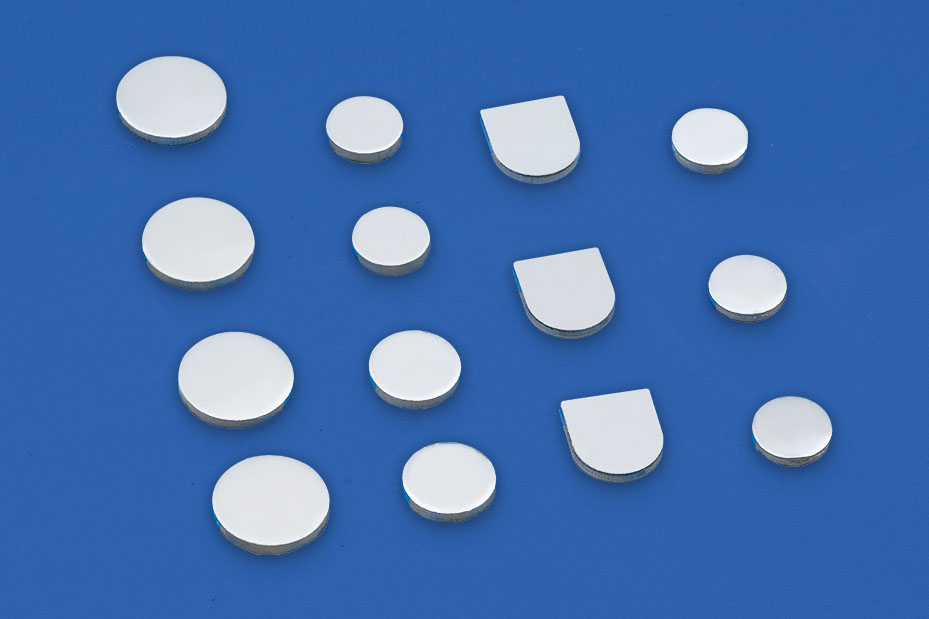

Electrical contact

Electrical contact

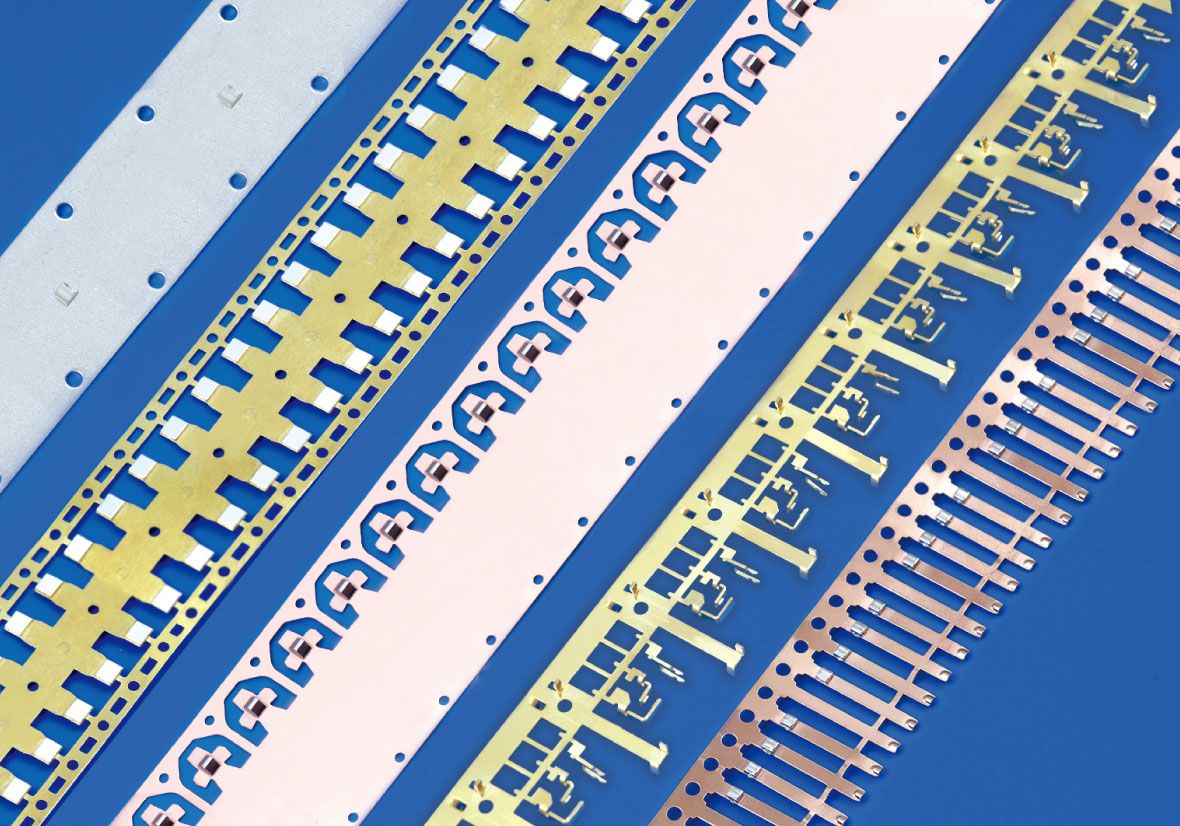

Instrument car parts

Instrument car parts

Contact welding assembly

Contact welding assembly ABOUT US

Baolixiang is specialized in high-tech manufacturers such as contact welding components, contact welding alloy materials, silver contacts, electric contacts,silver copper inlay composites, etc. It introduces the most advanced production equipment, manufacturing process and production technology of contact welding in Switzerland and Germany, and is equipped with high-precision testing instruments. It has a compl…

Quality assurance

The production management site adopts 6S management. Each area has a special person in charge.

Hierarchical quality supervision is adopted to ensure that defective products do not flow into the market.

From raw materials to sales, various management controls and data analysis are naturally generated.

Super large finished products and mold warehouse, providing customers with high-quality protection.

ReBCO coated high-temperature superconducting composite tape can realize superconductive state in liquid nitrogen environment, and has excellent advantages such as high critical magnetic field and high critical current. It has wide application prospects in new energy development and utilization, modern transportation, electric power transportation …

Yueqing Baolixiang Alloy Technology Co., Ltd. specializes in contact welding components Contact welding alloy materials, silver contacts, electrical contacts, silver copper inlaid composite sheets, etc., sincerely welcome customers at home and abroad, and sincerely invite technical talents to join!

Current has a greater effect on heat generation than both time and pressure. Therefore, the current parameter output must be strictly controlled in the welding process. If the welding current is too small to form a core or the size of the core is small, the strength of the welding point is small; If the welding current is too large, the surface and…

In order to ensure the strength of silver contact solder joint, the welding time and welding current can complement each other within a certain range. In order to obtain a certain strength of the solder joint and ensure the beauty of the solder joint, large current and short time can be used.

The electrode pressure has an obvious effect on the total resistance between the two electrodes. The electrode pressure is small and it is easy to generate splashes. With the increase of the electrode pressure, the total resistance decreases. When the electrode pressure increases and the welding current remains unchanged, the heat generation reduct…

Since the contact area of the electrode determines the current density, and the resistivity and thermal conductivity of the electrode material are related to the generation and loss of heat, the shape and material of the electrode have a significant impact on the formation of the nugget. With the deformation and wear of the electrode tip, the conta…

1. Advanced intermediate frequency inverter control system is adopted, which is more environmentally friendly and energy-saving, and the welding quality is higher;2. Adopt imported pneumatic components, Mitsubishi PLC, Winton touch screen and other large brand components to further improve the stability of the welding machine and ensure the product…

Silver point static contact spot welding machine is applicable to welding of electronic components, contact welding of circuit breakers, spot welding of power lines, assembly and welding of magnetic components of molded case circuit breakers, etc.